How to Node P&IDs for a HAZOP

To make a chemical or industrial process easier to analyze in a HAZOP study, the process is split up into different sections, called nodes. It is often best practice to determine nodes based on consistent parts of a process, whether they are portions of the main process or separate support systems. This allows HAZOP participants to be thinking consistently about each process instead of jumping back and forth between separate materials, phases or processes. Ultimately, the size and sequence of the nodes will determine the efficiency of the HAZOP.

Tips for Node Creation

Perform a high level review of all the P&IDs and find the main process flows and functions. Take note of major equipment and branches in the process such as at separators and reactors

Keep nodes to one substance and one phase (liquid or gas) and separate them by colour. Provide a numbered legend to the HAZOP team

Reserve node breaks for process/substance/phase interfaces such as separators, boilers, condensers, chemical injection joins, PSVs and sometimes manual valves for things such as drain systems

Order the nodes following the general process flow and with main processes first and support systems later

In large processing plants, nodes may also be divided by process unit if different operators or engineers are responsible for different units

Common Types Nodes

Chemical injection

Emulsion

Produced Water

Sales Oil or Gas

Sour oil, gas or water

High pressure steam, low pressure steam

Boiler feed water

Chemicals: antifoam, amine, methanol, etc.

Flare

Blanket gas

Instrument Air

Drain

Firewater/Foam system

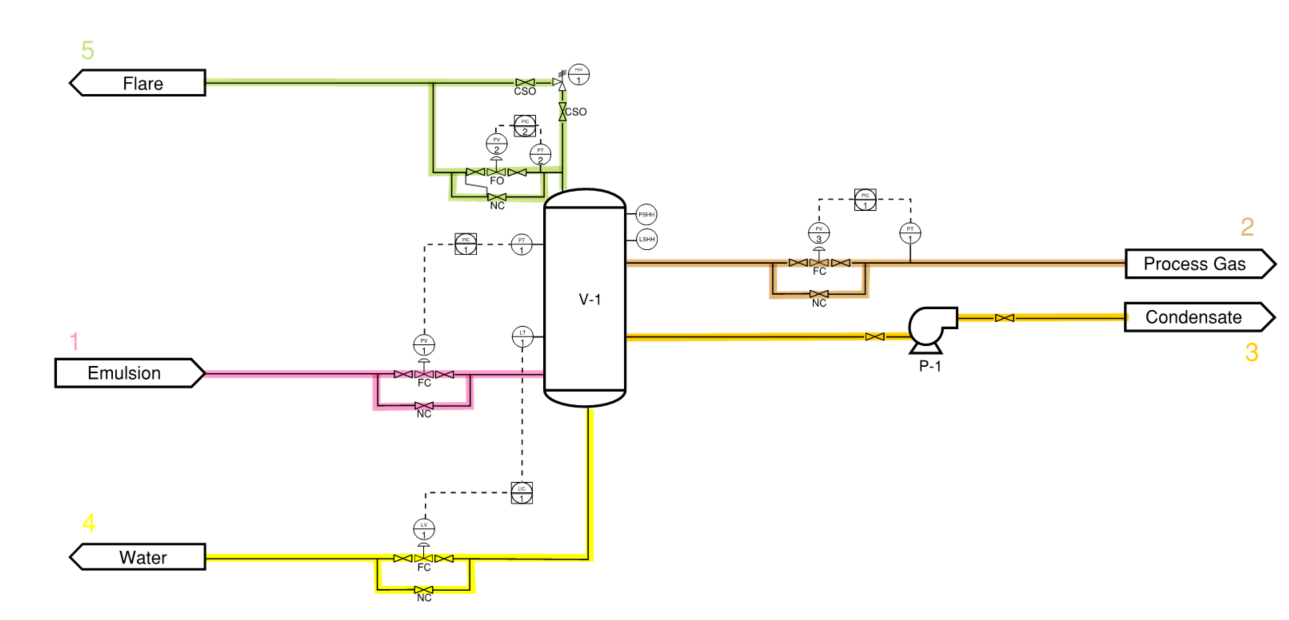

Let’s take a look at this simplified example below.

Here, we have a simplified P&ID that shows a vessel that separates an incoming emulsion into 3 different phases: process gas, condensate and water. Since all of these process streams have different physical and chemical properties, they have all been nodded separately and with a distinct color.