What does ALARP mean?

When designing industrial facilities, it is imperative to design the system as safe as possible, so as to minimize the risk of injury, illness or even death for those who work at the plant. However, no industrial activity is entirely free from risk. That being said, companies try to achieve a risk level that satisfies to requirement to be "as low as reasonably practicable", or "ALARP" for short.

Using the terminology "reasonably practicable" allows teams to set their own safety goals, rather than having rigid and prescriptive rules around safety system design. Having this type of inherent flexibility in the design process is advantageous because it allows a company to design a system that is best suited for them and their operations. However, it has its drawbacks, too. Deciding whether a risk is ALARP can be difficult because the concept isn't strictly defined, and therefore requires all stakeholders need to exercise their best judgement and come to a consensus.

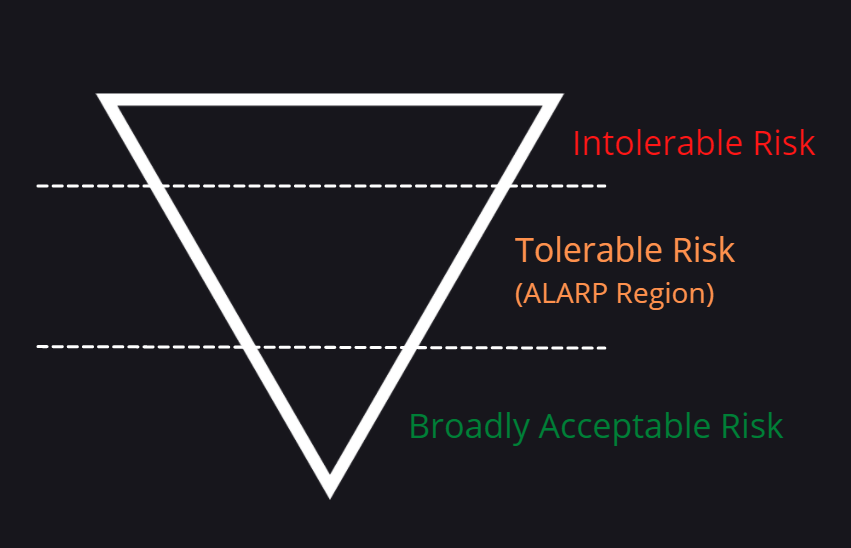

If the risk falls in the intolerable risk section in the triangle above, it signals additional safeguards or design changes are required. The ALARP principle can be used to define a broadly acceptable/tolerable region, and the residual risk of any one cause should fall in this region or near the bottom of the tolerable region.

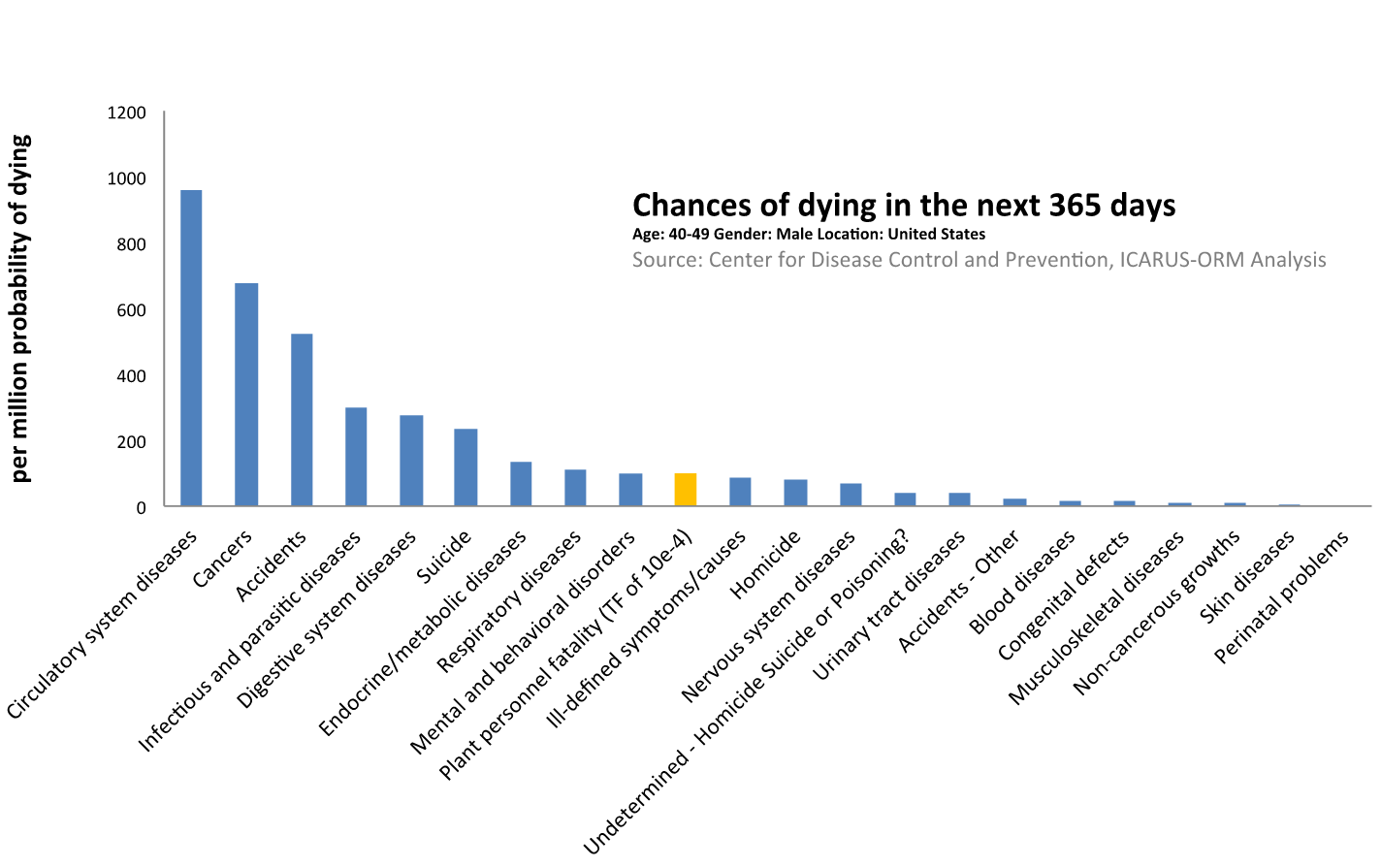

The most common way to determine whether a risk has been reduced to a level that is ALARP is to use a combination of a tolerable event frequency (TEF) and a cost-benefit evaluation, as this will provide the justification for whether additional risk-reducing measures should be implemented. The purpose of the ALARP principle is to provide guidance to companies that drives them to implement safe systems, without overdesigning the system to a level that is not necessary. The Major Industrial Accidents Council of Canada has Guidelines for Acceptable Levels of Risk for the chance of an individual fatality for different environments. Industrial workplaces fall into the area of a 1 in 10,000 chance per year or less. This is equivalent to ≤ 1 in 10-4/year and ≤ 100 in 1 million/year, as shown in the graphic below. If the system design meets this tolerable event frequency, then the risk has been reduced to a practicable level . For a risk to be ALARP, it must also be possible to demonstrate that the cost involved in reducing the risk further is grossly disproportionate to the benefit gained. If a certain design can be improved with minimal cost, and the improvement will reduce the risk significantly, the current design is unlikely to be considered ALARP.